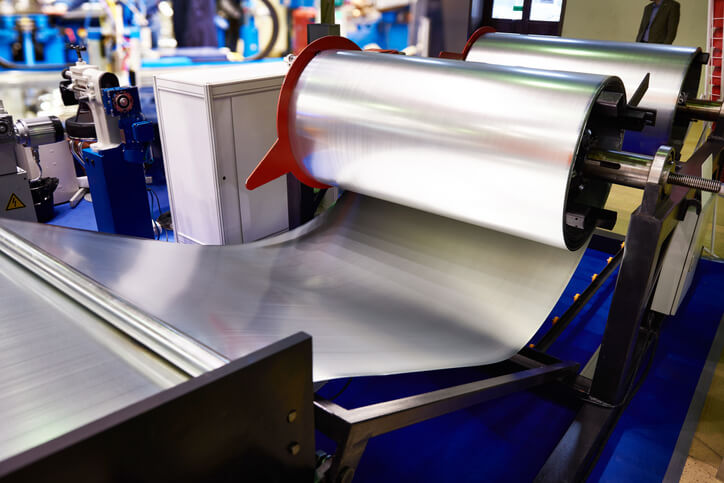

Sheet metal fabricated components

A Manufacturer of custom industrial fabrication & sheet metal fabrications. Our company will provide customer-requested products and services in Gujarat.

-

Sheet Metal Fabrication:

Sheet metal fabrication involves transforming flat sheets of metal into a variety of shapes and products through cutting, bending, and assembling processes. This method is widely used in industries such as automotive, aerospace, construction, and consumer electronics.

-

Key Services:

- Laser Cutting: Precision cutting of metal sheets to create intricate shapes and designs.

- Bending: Forming metal sheets into desired angles and shapes using press brakes.

- Welding: Joining metal parts together to create strong, durable structures.

- Punching: Creating holes and shapes in metal sheets using punch presses.

- Assembly: Combining different fabricated parts into final products or assemblies.

Applications:

- Automotive body panels

- Industrial machinery components

- HVAC systems

- Enclosures and cabinets

- Metal furniture

-

-

Stainless Steel Fabrication:

Stainless steel fabrication focuses on creating products from stainless steel, known for its corrosion resistance, strength, and aesthetic appeal. This type of fabrication is essential for industries that require durable and hygienic solutions, such as food processing, pharmaceuticals, and medical devices.

Key Services:

- Cutting and Shaping: Utilizing laser cutting, water jet cutting, and CNC machining to achieve precise dimensions.

- Welding and Joining: Employing TIG and MIG welding techniques to ensure strong and clean welds.

- Polishing and Finishing: Enhancing the surface finish to meet aesthetic and functional requirements.

- Custom Fabrication: Tailoring products to specific client needs, from kitchen equipment to architectural features.

- Assembly and Installation: Providing complete solutions from fabrication to on-site installation.

Application:

- Commercial kitchen equipment

- Medical and pharmaceutical equipment

- Architectural and structural components

- Food and beverage processing equipment

- Chemical processing tanks

-

Aluminium Fabrication:

Stainless steel fabrication focuses on creating products from stainless steel, known for its corrosion resistance, strength, and aesthetic appeal. This type of fabrication is essential for industries that require durable and hygienic solutions, such as food processing, pharmaceuticals, and medical devices.

Key Services:

- Cutting and Machining: Using precision tools like CNC machines and laser cutters to shape aluminium components.

- Extrusion: Creating complex cross-sectional profiles by forcing aluminium through a die.

- Welding: Specialised welding techniques like TIG welding to ensure high-strength joints.

- Forming and Bending: Shaping aluminium sheets and profiles to required specifications.

- Finishing: Applying anodizing, powder coating, and other finishes to enhance durability and aesthetics.

Applications:

- Aircraft components

- Automotive parts

- Building facades and roofing

- Marine and shipbuilding parts

- Consumer electronics enclosures

Each type of fabrication offers unique benefits and caters to specific industry needs, ensuring high-quality, durable, and efficient solutions for a wide range of applications.

For more information Follow us – Home | Linkedin | IndiaMart | TradeIndia